|

Albion Mark™

Peter Johnsson Museum Collection™

Tritonia™

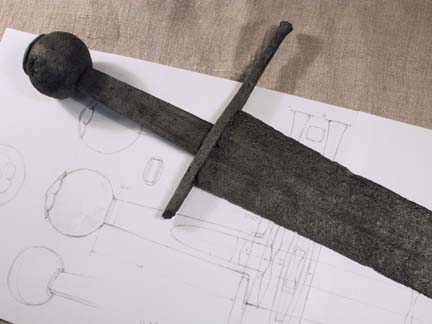

A

faithful recreation of an historical sword named after its find site,

an area now known as "Tritonia" in the medieval part of Stockholm, Sweden.

An archaeological excavation at the site yielded the remnants of a pier,

and this extraordinary sword.

It was still in its scabbard and remarkably intact when it was awakened

from its sleep in the muddy clay of the medieval shoreline (missing only

part of one arm of the cross-guard, a section of the point and the organic

portions of the grip). The original sword is now on display at the Museum

of Medieval Stockholm, Sweden.

The

sword is a stunning eye-catcher and presented many interesting challenges

during the process of reconstruction. It was obviously made by a master

of the craft and combines awesome cleaving power with agility and speed.

Despite its hefty weight it is smooth and responsive in handling. Its

blade, tang, cross and pommel were skillfully forged with a good eye for

beautiful proportions and a deep understanding of the dynamic qualities

of a broad slashing sword of such imposing dimensions. A distinguishing

feature is how the distal taper is designed to give support and stiffness

to the thin cutting section of the blade.

A

very similar sword with the same broad blade and spherical pommel is seen

in a sculpture in the “Easter Shrine” of the Cathedral, Constance, dated

to 1300, depicting a soldier sleeping by the tomb of Christ. Weapons like

these were effectively wielded from horseback and were popular during

the later part of the 13th C and the first half of the 14th C.

The

sword made in the workshops of Albion is a direct result of a project

for the Museum of Medieval Stockholm. Swordsmith Peter Johnsson was commissioned

to forge an exact reconstruction that was to be exhibited alongside the

original.

The knowledge gained during this project is now resulting in a faithful

and highly realistic reconstruction made by the skilled artisans of Albion.

No effort is spared to make the swords true to the original not only in

dimensions but also in performance and aesthetic details.

The

blades are hand-ground and finished to a high satin finish. Each blade

is individually heat treated in Albion's Shop for maximum flexibility

and cutting performance. All of our blades are thoroughly tested to destruction

to ensure that they are as durable (or more) than a period original (see

the results of one such testing session here.).

The wooden core of the grip is bound with cord and covered with leather.

The cross with its gently flaring ends, its ball pommel and florette are

all hand finished and mounted to fit individual blades.

Specifications

Overall length: 39" (99 cm)

Blade length: 33" (83.8 cm)

Blade width (at base): 2.5" (6.35 cm)

COG: 4.75" from cross (12 cm)

COP: 22" from cross (55.9 cm)

Weight: 3 lbs 6 oz (1.53 kilos)

Read

Customer Testimonials about the Tritonia here.

Read

a hands-on review

of the Tritonia on myArmoury.com

Tritonia

Type XIIIb.... $1628

Convenient

payment plans are available for qualified

customers

This

sword is offered in a limited edition

of 1,000 swords worldwide.

Handmade

scabbard designed by Peter Johnsson, in a style popular in the late 13th

C early 14th C.

See photos and complete description here.

Tritonia Scabbard.... $1,200

Read an impartial review by Patrick Kelly of the Tritonia Sword at

myArmoury.com:

| |

Peter

Johnsson on The Tritonia

|

Peter

Johnsson's original reconstruction of the Tritonia (and scabbard),

on display with the original sword at

Peter

Johnsson's original reconstruction of the Tritonia (and scabbard),

on display with the original sword at

the Museum of Medieval Stockholm |

"This

sword is a big one.

The blade is broad and bold, yet still graceful. It is definitely

one of the largest single hand swords I have handled.

The original weighs some 1.4 kilos, even as one arm of the cross

and a piece of the point is missing.

The first impression when I saw it was its imposing size and beautiful

proportions. There is a crispness in the forging of pommel, tang

and cross.

The blade has interesting dimensions. At the base the width flares

gracefully. Along the rest of the blade it tapers only very little

from around four inches from the cross to the point. This lends

a dynamic quality to the design.

The real interest is in the way its distal taper is defined. It

is not straight but varies so that the stiffness in the middle is

optimized while the point area is as light as possible without compromising

strength. This also helps handling characteristics.

A wide, long and rather heavy sword like this needs a careful distribution

of mass not to become cumbersome.

The study of this sword gave valuable new insights to this problem.

It is a very worn slogan, but this sword really needs to be handled

to be appreciated. Its weight and responsive balance makes it very

aggressive in cutting.

I would guess that this was a cavalry weapon, perhaps even a knightly

sword judging by its quality and understated elegance.

We held a little cutting session with tatami mats in the Albion

workshops when I delivered the prototypes. The prototype Tritonia

sliced through single, double and triple mat rolls with equal ease.

It was possible to make good clean cuts some 6-7 inches apart, both

diagonally and horizontally.

Judging from these tests, it is clear that a clean hit with this

sword would be devastating.

I would like to say though that the real value in the making of

this sword was not to produce a sword that is a excellent cutter,

but to find a way to translate the working procedures from my smithy

to the workshops of Albion.

There are critical but subtle details in the shaping of the blade

and the managing of mass distribution and balance that puts high

demand on the skill of the craftsmen involved and the production

methods.

At first I was not thrilled about the spherical pommel, but it is

a typical feature on some of the Scandinavian swords of this period.

Before long I found myself having no reservations to its pommel.

It looked just right and I would not want to replace it to something

else. A wheel pommel on this sword would make it more mainstream.

It would loose much of its personality.

The pommel of the original is solid and clearly forged, not cast.

The hole that takes the tang is slightly too wide (by a millimeter

or so on each face of the tang). This gap is wedged with thin wooden

slats that are well preserved and still clearly visible.

This very slight "hollowness" is something we have taken into account

in the making of the reconstruction at Albion. Not having a hole

so large that wedges are needed, but by removing a slight amount

of material down the centre of the pommel, the tang is still firmly

wedged in place from the base to the rivet and we still get the

balance right.

After having worked with the Tritonia on and off for more than two

years it has sort of passed beyond liking or not liking. Of course

I am fascinated with it and love it, but it has rather taken a place

among the extended family, so to say.

The Tritonia has taught me some important things and because of

that I am eternally grateful to its original maker (or makers).

The sword as a whole has very impressive proportions and is clearly

the result of the work of a master craftsman. As such it merits

a closer look.

To

put into production a sword at custom quality level that is constant

not only in dimensions, but also true to the idea of the original

sword when it was new, is challenging.

It has been an interesting and very inspiring period working as

a consulting swordsmith and designer with Albion. I hope that you´ll

find these swords an interesting addition to what is available on

the market today."

|

|

|

--

Peter Johnsson

|

|